SOPPEC PureSPRAYTM

Ultra-fast line marking system

What can you expect from a floor marking solution?

That it allows you to easily create straight lines, with visible and durable marking and with no clogging. And, of course, that it is quick.

The SOPPEC PureSPRAY™ system guarantees all this!

SOPPEC PureSPRAYTM system

Clean and precise marking, which does not require masking plates to maintain the quality of lines...

The SOPPEC PureSPRAY™ system benefits from all SOPPEC’s expertise in the field of spray marking. The combination of a unique formulation of resin, pigments and propellant, the exclusive design of the aerosol, spray nozzle + trolley combo, guarantees “clean” marking, which does not need masking edges to maintain the quality of lines.

The SOPPEC PureSPRAY™ system offers you fast, precise and mist-free marking.

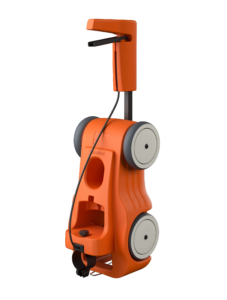

The central position of the drawbar guarantees outstanding stability and minimises the user’s interference during marking. The wheels with a wide tread (32 mm) and long wheelbase ensure straight running.

The aerosol can positioning is intuitive thanks to the exclusive SOPPEC PureSPRAY™ nozzle holder. The spray zone is protected and optimised in order not to disrupt the flow of paint. A protective cover (optional) further increases protection for spraying in windy conditions.

The compact shape facilitates marking up to 60 mm from obstacles at the front and 79 mm from obstacles at the side. The marking width is continuously adjustable from 5 to 12 cm.

The trolley is assembled without the need for tools: simply put the drawbar and the aerosol holder in place and hand tighten the 2 locking nuts. It can be put away in a flash: just tip the trolley onto its nose using the handle and position the drawbar at the back.

The central position of the drawbar guarantees outstanding stability and minimises the user’s interference during marking. The wheels with a wide tread (32 mm) and long wheelbase ensure straight running.

The aerosol can positioning is intuitive thanks to the exclusive SOPPEC PureSPRAY™ nozzle holder. The spray zone is protected and optimised in order not to disrupt the flow of paint. A protective cover (optional) further increases protection for spraying in windy conditions.

The compact shape facilitates marking up to 60 mm from obstacles at the front and 79 mm from obstacles at the side. The marking width is continuously adjustable from 5 to 12 cm.

The trolley is assembled without the need for tools: simply put the drawbar and the aerosol holder in place and hand tighten the 2 locking nuts. It can be put away in a flash: just tip the trolley onto its nose using the handle and position the drawbar at the back.  For the first time on the market, the user is enjoying two quick and simple application modes with one single trolley:

For the first time on the market, the user is enjoying two quick and simple application modes with one single trolley: